Study of the Phase Composition and Kinetics of the Metal Leaching Process Using Electrohydropulse Discharge on the Waste from the Zhezkazgan Concentrating Plants

DOI:

https://doi.org/10.31489/2959-0663/2-25-13Keywords:

hydropulse discharge, pulp, laboratory cell, ammonium bifluoride, tailings samples, metals, acid, copperAbstract

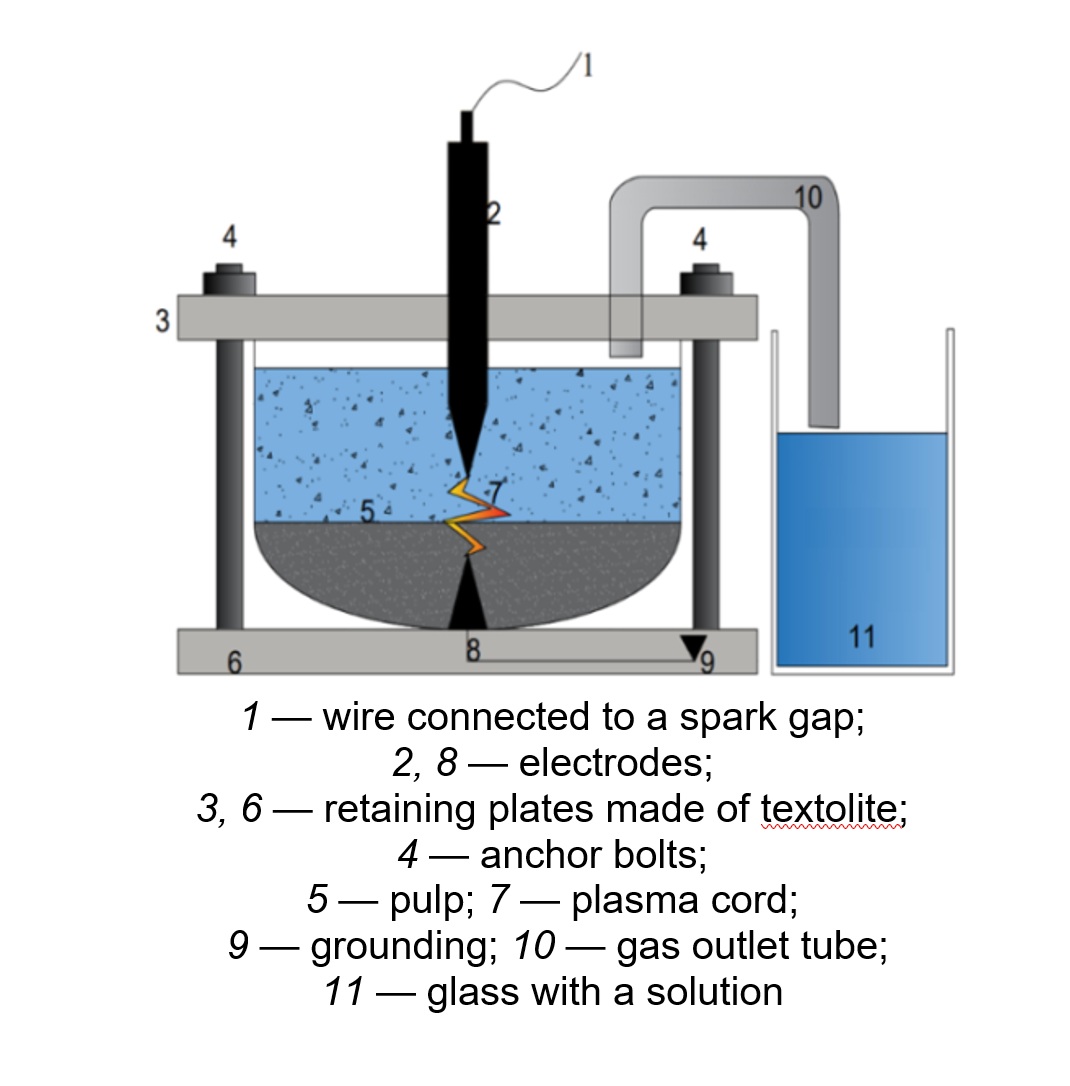

This work involved conducting X-ray phase analysis and energy-dispersive spectroscopy (EDS), for the first time, as well as examining the kinetics of metal extraction processes from the tailings of the Zhezkazgan Concentration Plant (ZhCP) before and after their treatment. Based on the results of X-ray diffraction results, the main diffraction peaks have been found to corresponded to silicon-containing or silicate minerals, as well as phases characteristic of Cu2S, CuFe2S3, and ZnS. Following electrohydropulse discharge leaching, the silicates (SiO2) were partially destroyed, releasing metal oxides. The elemental composition of the tailings was analyzed using electron probe X-ray microanalysis. The EDS analysis revealed the presence of 13 elements, the most intense lines of which were silicon, oxygen, and aluminum, while the remaining elements were found in minor quantities. The activation energy was determined graphically using the Arrhenius equation based on the rate constants (lnK) at various temperatures and exposure times to electrohydropulse discharge. To determine the kinetics of the leaching process, a high-temperature thermometer was installed on the reactor to record the temperature of the slurry, including the solution reaction mixture. During the hydropulse discharge process, the temperature of the reaction medium rose to 60 °C over 30 minutes.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Askhat S. Borsynbayev, Yedige S. Mustafin , Khylysh B. Omarov , Aigul A. Muratbekova , Daulet A. Kaykenov , Daniyar T. Sadyrbekov , Asanali A. Ainabayev, Abylaikhan N. Bolatbay; Milana A. Turovets

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-NC-ND 4.0) that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.