Graft Polymerization of Octadecyl Acrylate on PET Track-Etched Membranes for Direct Contact Membrane Distillation

DOI:

https://doi.org/10.31489/2959-0663/3-25-1Keywords:

track-etched membranes, UV-initiated grafting, membrane distillation, water desalination, poly(ethylene terephthalate), water flux, water treatment, polymerizationAbstract

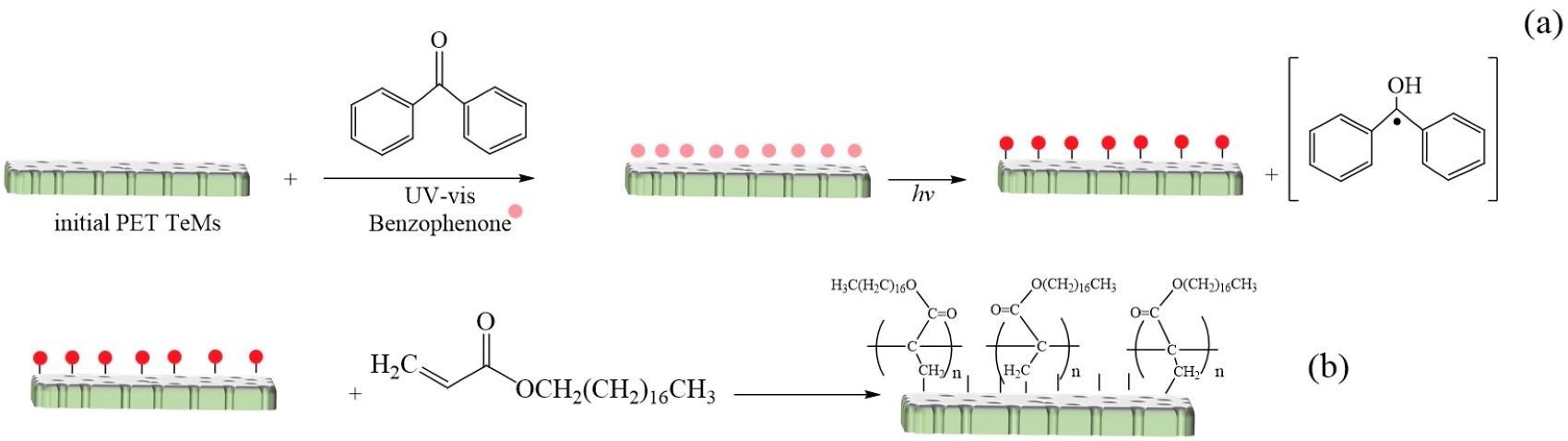

Water purification is a critical environmental and social issue of our era. The contamination of water sources by industrial waste, agricultural chemicals, household debris, and plastic pollution significantly degrades the quality of available freshwater. This poses substantial threats to human health and ecosystems. While water is plentiful on Earth, only a limited amount is freshwater that people can safely consume. Population growth, urbanization, and climate change are further exacerbating this scarcity, especially in arid regions. This study examines the membrane distillation process employing ion-track membranes. Hydrophobic poly(ethylene terephthalate) ion-track membranes with increased pore diameters were synthesized via UV-induced graft polymerization of octadecyl acrylate on the membrane surface. Hydrophobic properties were assessed through water contact angle measurements. Fourier transform infrared spectroscopy analyzed functional groups while scanning electron microscopy examined surface morphology. The hydrophobic membranes were subsequently evaluated for desalination performance using direct contact membrane distillation method with saline solutions of varying concentrations. The effect of pore size and feed salt concentration on permeate flux and salt rejection efficiency was systematically examined. Membranes with a contact angle of 95±3° were tested in saline solutions with concentrations from 7.5 to 30 g/L.

References

Shalaby, S. M., Zayed, M. E., Hammad, F. A., Menesy, A. S., & Elbar, A. R. A. (2024). Recent advances in membrane dis-tillation hybrids for energy-efficient process configurations: Technology categorization, operational parameters identification, and energy recovery strategies. Process Safety and Environmental Protection, 190, 817–838. https://doi.org/10.1016/J.PSEP.2024.07.098 DOI: https://doi.org/10.1016/j.psep.2024.07.098

Wang, Y., Liu, X., Ge, J., Li, J., & Jin, Y. (2023). Distillation performance in a novel minichannel membrane distillation device. Chemical Engineering Journal, 462, 142335. https://doi.org/10.1016/J.CEJ.2023.142335 DOI: https://doi.org/10.1016/j.cej.2023.142335

Khalifa, A., Etman, A., El-Adawy, M., Alawad, S. M., & Nemitallah, M. A. (2025). Development of membrane distillation powered by engine exhaust for water desalination. Applied Thermal Engineering, 258, 124839. https://doi.org/10.1016/J.APPLTHERMALENG.2024.124839 DOI: https://doi.org/10.1016/j.applthermaleng.2024.124839

Khalifa, A., Kotb, M., & M. Alawad, S. (2025). Energy-efficient and cost-effective water desalination using membrane dis-tillation with air-cooled dehumidifier bank. Energy Conversion and Management: X, 25, 100844. https://doi.org/10.1016/J.ECMX.2024.100844 DOI: https://doi.org/10.1016/j.ecmx.2024.100844

AlMehrzi, M., Shaheen, A., Ghazal, A., Almarzooqi, N., Raza, A., Zhang, T., & AlMarzooqi, F. (2024). Photothermal ZrN composite membranes for solar-driven water distillation. Journal of Environmental Chemical Engineering, 12(5), 113763. https://doi.org/10.1016/J.JECE.2024.113763 DOI: https://doi.org/10.1016/j.jece.2024.113763

Shaikh, J. S., Aswalekar, U., Ismail, S., & Akhade, A. (2024). The potential of integrating solar-powered membrane distilla-tion with a humidification–dehumidification system to recover potable water from textile wastewater. Chemical Engineering and Processing — Process Intensification, 205, 110036. https://doi.org/10.1016/J.CEP.2024.110036 DOI: https://doi.org/10.1016/j.cep.2024.110036

Tian, M., Yin, Y., Zhang, Y., & Han, L. (2025). Membrane distillation goes green: Advancements in green membrane prep-aration and renewable energy utilization. Desalination, 597, 118344. https://doi.org/10.1016/J.DESAL.2024.118344 DOI: https://doi.org/10.1016/j.desal.2024.118344

Zhang, N., Zhang, J., Gao, C., Yuan, S., & Wang, Z. (2025). Emerging advanced membranes for removal of volatile organic compounds during membrane distillation. Desalination, 597, 118372. https://doi.org/10.1016/J.DESAL.2024.118372 DOI: https://doi.org/10.1016/j.desal.2024.118372

Abejón, R., Romero, J., & Quijada-Maldonado, E. (2024). Potential of membrane distillation for water recovery and reuse in water stress scenarios: Perspective from a bibliometric analysis. Desalination, 591, 117989. https://doi.org/10.1016/J.DESAL.2024.117989 DOI: https://doi.org/10.1016/j.desal.2024.117989

Ahmadi, H., Ziapour, B. M., Ghaebi, H., & Nematollahzadeh, A. (2024). Optimization of vacuum membrane distillation and advanced design of compact solar water heaters with heat recovery. Journal of Water Process Engineering, 67, 106212. https://doi.org/10.1016/J.JWPE.2024.106212 DOI: https://doi.org/10.1016/j.jwpe.2024.106212

Park, H. J., Park, H., Kim, J., Lee, K., Naddeo, V., & Choo, K. H. (2024). Enhancing sustainability: Upcycled membrane distillation for water and nutrient recovery from anaerobic membrane bioreactor effluent. Chemical Engineering Journal, 498, 155267. https://doi.org/10.1016/J.CEJ.2024.155267 DOI: https://doi.org/10.1016/j.cej.2024.155267

Pawar, R., & Vidic, R. D. (2024). Impact of surfactants used in oil and gas extraction on produced water treatment by mem-brane distillation. Desalination, 586, 117906. https://doi.org/10.1016/J.DESAL.2024.117906 DOI: https://doi.org/10.1016/j.desal.2024.117906

Zhang, R., Chen, Y., Wang, H., Duan, X., & Ren, Y. (2024). A Janus membrane with silica nanoparticles interlayer for treating coal mine water via membrane distillation. Separation and Purification Technology, 350, 127995. https://doi.org/10.1016/J.SEPPUR.2024.127995 DOI: https://doi.org/10.1016/j.seppur.2024.127995

Maliwan, T., & Hu, J. (2025). Release of microplastics from polymeric ultrafiltration membrane system for drinking water treatment under different operating conditions. Water Research, 274, 123047. https://doi.org/10.1016/J.WATRES.2024.123047 DOI: https://doi.org/10.1016/j.watres.2024.123047

Park, Y., Choi, Y., Choi, J., Ju, J., Kim, B., & Lee, S. (2020). Effect of vibration on fouling propensity of hollow fiber mem-branes in microfiltration and membrane distillation. Desalination and Water Treatment, 192, 11–18. https://doi.org/10.5004/DWT.2020.25151 DOI: https://doi.org/10.5004/dwt.2020.25151

Ortega-Bravo, J. C., Guzman, C., Iturra, N., & Rubilar, M. (2023). Forward osmosis, reverse osmosis, and distillation mem-branes evaluation for ethanol extraction in osmotic and thermic equilibrium. Journal of Membrane Science, 669, 121292. https://doi.org/10.1016/J.MEMSCI.2022.121292 DOI: https://doi.org/10.1016/j.memsci.2022.121292

Ali, A. S., & Bounahmidi, T. (2024). Coupling of photovoltaic thermal with hybrid forward osmosis-membrane distillation: Energy and water production dynamic analysis. Journal of Water Process Engineering, 64, 105710. https://doi.org/10.1016/J.JWPE.2024.105710 DOI: https://doi.org/10.1016/j.jwpe.2024.105710

Otávio Rosa e Silva, G., Rodrigues dos Santos, C., Souza Casella, G., Pinheiro Drumond, G., & Cristina Santos Amaral, M. (2025). Membrane fouling in integrated forward osmosis and membrane distillation systems — A review. Separation and Purifica-tion Technology, 356, 129955. https://doi.org/10.1016/J.SEPPUR.2024.129955 DOI: https://doi.org/10.1016/j.seppur.2024.129955

Wang, L., Sun, X., Gao, F., Yang, Y., & Song, R. (2024). Solar membrane distillation: An emerging technology for reverse osmosis concentrated brine treatment. Desalination, 592, 118124. https://doi.org/10.1016/J.DESAL.2024.118124 DOI: https://doi.org/10.1016/j.desal.2024.118124

Li, X., García-Payo, M. C., Khayet, M., Wang, M., & Wang, X. (2017). Superhydrophobic polysul-fone/polydimethylsiloxane electrospun nanofibrous membranes for water desalination by direct contact membrane distillation. Journal of Membrane Science, 542, 308–319. https://doi.org/10.1016/J.MEMSCI.2017.08.011 DOI: https://doi.org/10.1016/j.memsci.2017.08.011

Bahrami Eynolghasi, M., Mohammadi, T., & Tofighy, M. A. (2022). Fabrication of polystyrene (PS)/cyclohexanol-based carbon nanotubes (CNTs) mixed matrix membranes for vacuum membrane distillation application. Journal of Environmental Chemical Engineering, 10(4), 108175. https://doi.org/10.1016/J.JECE.2022.108175 DOI: https://doi.org/10.1016/j.jece.2022.108175

Omar, N. M. A., Othman, M. H. D., Tai, Z. S., Kurniawan, T. A., Puteh, M. H., Jaafar, J., Rahman, M. A., Bakar, S. A., & Abdullah, H. (2024). A review of superhydrophobic and omniphobic membranes as innovative solutions for enhancing water desal-ination performance through membrane distillation. Surfaces and Interfaces, 46, 104035. https://doi.org/10.1016/J.SURFIN.2024.104035 DOI: https://doi.org/10.1016/j.surfin.2024.104035

Jilagam, N. K., Vaghela, G., Chakrabarty, T., Guo, J., Farid, M. U., Jeong, S., Shon, H. K., An, A. K., & Deka, B. J. (2024). Frontier of metal-organic framework nanofillers for pre-eminent membrane distillation applications. Desalination, 592, 118127. https://doi.org/10.1016/J.DESAL.2024.118127 DOI: https://doi.org/10.1016/j.desal.2024.118127

Nthunya, L. N., Chong, K. C., Lai, S. O., Lau, W. J., López-Maldonado, E. A., Camacho, L. M., Shirazi, M. M. A., Ali, A., Mamba, B. B., Osial, M., Pietrzyk-Thel, P., Pregowska, A., & Mahlangu, O. T. (2024). Progress in membrane distillation processes for dye wastewater treatment: A review. Chemosphere, 360, 142347. https://doi.org/10.1016/J.CHEMOSPHERE.2024.142347 DOI: https://doi.org/10.1016/j.chemosphere.2024.142347

Jawed, A. S., Nassar, L., Hegab, H. M., van der Merwe, R., Al Marzooqi, F., Banat, F., & Hasan, S. W. (2024). Recent de-velopments in solar-powered membrane distillation for sustainable desalination. Heliyon, 10(11), e31656. https://doi.org/10.1016/J.HELIYON.2024.E31656 DOI: https://doi.org/10.1016/j.heliyon.2024.e31656

Guo, Q., Liu, Y., Li, T., Gao, L., Yin, S., Li, S., & Zhang, L. (2024). Enhancement and optimization of membrane distilla-tion processes: A systematic review of influential mechanisms, optimization and applications. Desalination, 586, 117862. https://doi.org/10.1016/J.DESAL.2024.117862 DOI: https://doi.org/10.1016/j.desal.2024.117862

Shakayeva, A. K., Yeszhanov, A. B., Borissenko, A. N., Kassymzhanov, M. T., Zhumazhanova, A. T., Khlebnikov, N. A., Nurkassimov, A. K., Zdorovets, M. V, Güven, O., & Korolkov, I. V. (2024). Surface Modification of Polyethylene Terephthalate Track-Etched Membranes by 2,2,3,3,4,4,5,5,6,6,7,7-Dodecafluoroheptyl Acrylate for Application in Water Desalination by Direct Contact Membrane Distillation. Membranes, 14(7). https://doi.org/10.3390/membranes14070145 DOI: https://doi.org/10.3390/membranes14070145

Yeszhanov, A. B., Korolkov, I. V, Dosmagambetova, S. S., Zdorovets, M. V, & Güven, O. (2021). Recent Progress in the Membrane Distillation and Impact of Track-Etched Membranes. Polymers, 13(15). https://doi.org/10.3390/polym13152520 DOI: https://doi.org/10.3390/polym13152520

Korolkov, I. V., Kuandykova, A., Yeszhanov, A. B., Güven, O., Gorin, Y. G., & Zdorovets, M. V. (2020). Modification of PET Ion-Track Membranes by Silica Nanoparticles for Direct Contact Membrane Distillation of Salt Solutions. Membranes, 10(11), 1–15. https://doi.org/10.3390/MEMBRANES10110322 DOI: https://doi.org/10.3390/membranes10110322

Korolkov, I. V., Gorin, Y. G., Yeszhanov, A. B., Kozlovskiy, A. L., & Zdorovets, M. V. (2018). Preparation of PET track-etched membranes for membrane distillation by photo-induced graft polymerization. Materials Chemistry and Physics, 205, 55–63. https://doi.org/10.1016/J.MATCHEMPHYS.2017.11.006 DOI: https://doi.org/10.1016/j.matchemphys.2017.11.006

Korolkov, I. V., Yeszhanov, A. B., Zdorovets, M. V., Gorin, Y. G., Güven, O., Dosmagambetova, S. S., Khlebnikov, N. A., Serkov, K. V., Krasnopyorova, M. V., Milts, O. S., & Zheltov, D. A. (2019). Modification of PET ion track membranes for mem-brane distillation of low-level liquid radioactive wastes and salt solutions. Separation and Purification Technology, 227, 115694. https://doi.org/10.1016/J.SEPPUR.2019.115694 DOI: https://doi.org/10.1016/j.seppur.2019.115694

Yeszhanov, A. B., Korolkov, I. V., Güven, O., Melnikova, G. B., Dosmagambetova, S. S., Borissenko, A. N., Nurkassimov, A. K., Kassymzhanov, M. T., & Zdorovets, M. V. (2024). Effect of hydrophobized PET TeMs membrane pore-size on saline water treatment by direct contact membrane distillation. RSC Advances, 14(6), 4034–4042. https://doi.org/10.1039/D3RA07475G DOI: https://doi.org/10.1039/D3RA07475G

Deng, J., Wang, L., Liu, L., & Yang, W. (2009). Developments and new applications of UV-induced surface graft polymeri-zations. Progress in Polymer Science, 34(2), 156–193. https://doi.org/10.1016/J.PROGPOLYMSCI.2008.06.002 DOI: https://doi.org/10.1016/j.progpolymsci.2008.06.002

Kravets, L., Vinogradov, I., Rossouw, A., Gorberg, B., Nechaev, A., & Apel, P. (2025). Functionalization of PET track-etched membranes with electrospun PVDF nanofibers for hybrid membranes fabrication in water desalination. Separation and Puri-fication Technology, 371(March), 133395. https://doi.org/10.1016/j.seppur.2025.133395 DOI: https://doi.org/10.1016/j.seppur.2025.133395

Yeszhanov, A. B., Shakayeva, A. Kh., Zdorovets, M. V., Borgekov, D. B., Kozlovskiy, A. L., Kharkin, P. V., Zheltov, D. A., Krasnopyorova, M. V., Güven, O., & Korolkov, I. V. (2025). Hybrid Membranes Based on Track-Etched Membranes and Nanofiber Layer for Water–Oil Separation and Membrane Distillation of Low-Level Liquid Radioactive Wastes and Salt Solutions. Membranes, 15(7), 202. https://doi.org/10.3390/membranes15070202 DOI: https://doi.org/10.3390/membranes15070202

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Arman B. Yeszhanov, Ilya V. Korolkov, Maxim V. Zdorovets

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-NC-ND 4.0) that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.